Insights

How to Build Better Tech Products with a Digital Twin

Building a virtual replica of your next product or service could give you all the answers you need to optimize performance, adoption and user satisfaction.

What is Digital Twin Technology?

A “digital twin” is a system which provides a real-time digital representation of some physical asset or process of interest, with the purpose of improving performance and efficiency. For example, NASA built a digital twin for Apollo 13 to simulate and assess conditions on the shuttle.

In general, a digital twin is thought to have three parts:

- A physical asset or product

- A virtual representation of that product

- A bi-directional data connection between the physical and virtual product

More specifically, a digital twin is a digital replica of an ‘operating asset’ that can:

- Display data it receives from live sensors

- Update a physics model for the operating asset with the received data

- Compute predictive results of operational status with artificial intelligence to aid in optimizing asset use

- Control the asset accordingly based on data

Why use digital twin technology?

Digital Twin technology provides engineering, maintenance and operations teams with stability and predictability during uncertain times. By aligning multiple engineering disciplines around a single source of verified data, risks can be minimized and identified early, time wasted sourcing and checking data is eliminated and a culture of collaboration between teams and stakeholders is fostered through greater transparency and bi-directional data flows.

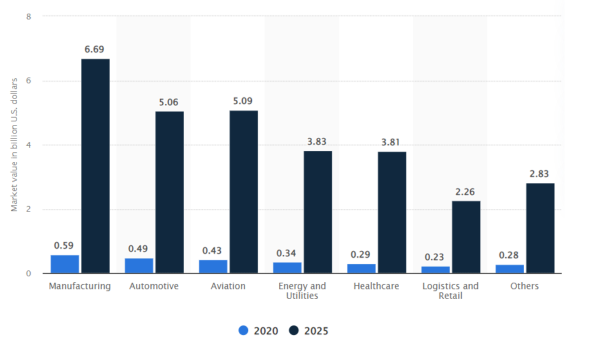

Global digital twin market size in the year 2020 and 2025, by industry

(in billions, USD)

Reference: https://www.statista.com

Here’s how digital twin solutions are transforming engineering projects:

- Real-time actionable asset information

- 2 months to deploy across the full business unit with a cloud solution

- 10% increased staff productivity

- Real-time visibility into operations so you can catch bottlenecks

- The ability to make data-driven decisions

How to utilize industry 4.0 technologies to create a digital twin

CAD

Building a 3D model requires Computer Aided Design (CAD) software to draw the digital representation of the physical asset.

IOT

Internet Of Things (IOT) is used to keep the connection between the physical asset and the digital twin. The sensors’ readings being transmitted online from the physical asset to the computer allows engineers to monitor things and simulates the performance of the physical asset.

Augmented reality

The image below shows a model of a digital twin displaying real-time parameters of working pipe and pumps. Augmented graphs like these can display critical parameters of equipment which helps track individual instrument performance. Beyond that, you can simulate parameters in a virtual digital twin before replicating those parameters to the actual system.

Big data analytics

When talking about building digital twins for products for humans, we need a huge amount of data to be analyzed so that the model can understand our attributes, needs, etc. This includes big data analytics covering things like the foods we like, the movies we watch, our daily routine and many other inputs.

Artificial intelligence

Artificial intelligence algorithms are needed when we allow our digital twins to make some decisions ‘on their own’ or interact with others.

How ChaiOne can help you implement a digital twin

The right resources: ChaiOne’s experience blending multiple technologies can be extremely helpful for implementing a digital twin. Without intimate knowledge and experience in technologies like CAD, IoT and augmented reality, it can be difficult to get the full benefits from a digital twin.

Experienced SMEs: We have experts in-house with a wide range of skill sets who know how to plan and implement a digital twin solution in a range of sectors and companies. Most of our SMEs come from the EPC, hydrocarbon and energy sectors.

Proven track record: ChaiOne is experienced in delivering major projects on time with accurate analytics to help you unleash the true value of this powerful model.